Description

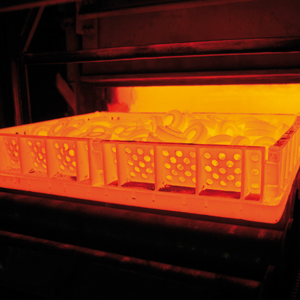

Custom Stainless Steel Forging

Custom stainless steel forging is a specialized manufacturing process where stainless steel is shaped under extreme pressure and heat to create high-strength, durable components tailored to specific applications. This process involves deforming stainless steel billets or ingots through repeated hammering or pressing, which aligns and refines the metal’s grain structure. The result is enhanced mechanical properties, such as increased strength, toughness, and resistance to wear and corrosion. Custom stainless steel forgings are essential in industries that require high-performance parts capable of withstanding harsh environments, such as aerospace, oil and gas, marine, and chemical processing.

One of the primary advantages of stainless steel forging is its ability to create components with superior corrosion resistance, making it ideal for applications in industries where the material is exposed to moisture, chemicals, and high temperatures. Custom stainless steel forgings offer flexibility in terms of shapes, sizes, and material grades, ensuring that the components meet the exact specifications of the application.

Key Features of Custom Stainless Steel Forging

- Corrosion Resistance: Stainless steel forgings provide exceptional resistance to rust, oxidation, and chemical corrosion, making them ideal for marine, chemical, and food processing environments.

- High Strength and Durability: The forging process increases the strength and toughness of stainless steel, resulting in parts that can withstand extreme pressure, wear, and stress.

- Enhanced Mechanical Properties: Custom stainless steel forgings have superior fatigue resistance, making them suitable for applications that involve repeated loading and unloading cycles.

- Customizable Designs: Stainless steel can be forged into various complex shapes and sizes to meet the unique needs of each application.

- Temperature and Heat Resistance: Forged stainless steel components can maintain their strength and integrity at high temperatures, making them ideal for high-heat applications.

Applications of Custom Stainless Steel Forging

- Aerospace Industry: In aerospace, custom stainless steel forgings are used to produce critical components such as turbine blades, landing gear parts, and engine components. These parts must be strong, corrosion-resistant, and capable of withstanding extreme conditions.

- Oil & Gas Industry: Stainless steel forgings are crucial in oil and gas exploration and production equipment, including valve bodies, drill collars, and pump shafts. The excellent corrosion resistance and durability of stainless steel make it ideal for harsh environments such as offshore platforms and refineries.

- Marine Industry: Marine applications demand materials with excellent resistance to saltwater corrosion. Stainless steel forgings are used for propeller shafts, rudder stocks, and other components exposed to seawater and high stresses.

- Food & Beverage Industry: In food processing, custom stainless steel forgings are used for equipment such as mixers, conveyors, and valves. The material’s corrosion resistance and hygienic properties make it ideal for maintaining cleanliness and preventing contamination.

- Chemical Processing: Stainless steel forgings are used in chemical plants for piping systems, valves, and pressure vessels, where resistance to corrosive chemicals and high temperatures is crucial.

- Power Generation: Forged stainless steel components such as turbine shafts, generator rotors, and heat exchanger components are essential in power plants. The high heat resistance and strength of stainless steel ensure reliable operation in these demanding environments.

- Automotive Industry: Stainless steel forgings are used for engine components, drive shafts, and suspension systems, providing excellent strength, durability, and corrosion resistance.

Grades of Custom Stainless Steel Forging

Different grades of stainless steel are used in custom forging to meet the specific requirements of various applications. These grades vary in terms of mechanical properties, corrosion resistance, and heat resistance.

| Material Grade | Type | Applications |

|---|---|---|

| SS304 | Austenitic Stainless Steel | General-purpose applications, food processing, and chemical equipment due to its corrosion resistance and weldability |

| SS316 | Austenitic Stainless Steel | Marine and chemical environments requiring superior corrosion resistance and strength |

| SS410 | Martensitic Stainless Steel | Pump shafts, valves, and turbine blades where hardness and wear resistance are essential |

| SS416 | Martensitic Stainless Steel | Applications that require high machinability and corrosion resistance, such as automotive parts and fasteners |

| SS17-4 PH | Precipitation-Hardening Stainless Steel | Aerospace, chemical processing, and oil & gas applications requiring high strength, toughness, and corrosion resistance |

| Duplex 2205 | Duplex Stainless Steel | Oil & gas, chemical processing, and marine environments needing a balance of strength and corrosion resistance |

| Super Duplex 2507 | Super Duplex Stainless Steel | High-pressure and corrosive environments such as subsea oil drilling and chemical processing |

| SS904L | Austenitic Stainless Steel | Extreme corrosion-resistant applications, such as chemical processing, acid handling, and seawater exposure |

| SS347 | Austenitic Stainless Steel | High-temperature applications like exhaust systems and boiler components due to its heat resistance and corrosion protection |

Benefits of Custom Stainless Steel Forging

- Corrosion and Heat Resistance: Forged stainless steel components are highly resistant to corrosion from water, chemicals, and heat, making them ideal for harsh environments.

- Superior Strength and Durability: The forging process improves the mechanical properties of stainless steel, resulting in parts with superior strength, toughness, and durability.

- Customizability: Stainless steel forgings can be customized to meet specific design requirements, offering flexibility in shapes, sizes, and grades.

- Improved Wear Resistance: Custom stainless steel forgings exhibit excellent wear and fatigue resistance, making them suitable for high-stress applications.

- Cost-Effective for High-Performance Parts: Stainless steel forgings offer long-term performance and durability, reducing the need for frequent replacements, thus saving costs over time.