Description

Deep Hole Drilling Services

Deep hole drilling services are essential for creating holes with high depth-to-diameter ratios in various materials. This specialized drilling process is used to produce holes that are typically deeper than 10 times the diameter of the hole, making it a critical technique in industries such as aerospace, automotive, oil & gas, and heavy engineering. The precision and quality required for deep hole drilling mean that this service demands advanced technology, skilled professionals, and cutting-edge machinery.

What is Deep Hole Drilling?

Deep hole drilling is a machining process designed to drill holes with extreme depth, ensuring accuracy and precision without sacrificing the integrity of the material being drilled. It differs from standard drilling due to the unique equipment and methodology that helps maintain straightness, surface finish, and dimensional accuracy even for long and deep holes.

The process typically employs coolant pressure, specialized drill bits, and custom fixturing to effectively evacuate chips and control temperature. There are several methods of deep hole drilling, including gun drilling, BTA (Boring and Trepanning Association) drilling, and Ejector drilling, each suited for different applications depending on the hole size, depth, and material type.

Key Features of Deep Hole Drilling:

- High Precision: Ensures tight tolerances even for deep holes.

- Effective Chip Evacuation: Special coolant pressure systems help remove chips efficiently.

- Excellent Surface Finish: Ensures smooth and burr-free hole surfaces.

- Straightness: Precision fixturing and techniques maintain excellent hole straightness, typically within 0.1 mm per meter.

Types of Deep Hole Drilling:

- Gun Drilling:

- Ideal for smaller diameter holes (1-50 mm) and deep drilling applications.

- Ensures high precision and excellent surface finish.

- Common in applications like rifle barrels, medical tools, and injection molds.

- BTA Drilling:

- Used for larger diameter holes (20 mm to over 400 mm).

- Efficient chip removal via internal coolant flow.

- Typically used in industries like oil & gas, aerospace, and heavy machinery.

- Ejector Drilling:

- A variant of BTA drilling suitable for deep, large-diameter holes.

- Common in applications like hydraulic cylinders and heat exchangers.

Applications of Deep Hole Drilling:

Deep hole drilling is employed in a variety of industries due to its versatility and precision. Some key applications include:

| Industry | Applications |

|---|---|

| Aerospace | Engine components, landing gear, and structural components. |

| Automotive | Drive shafts, engine blocks, crankshafts, and fuel injection systems. |

| Oil & Gas | Drill collars, casing components, and downhole tools. |

| Medical | Surgical tools, implants, and prosthetics. |

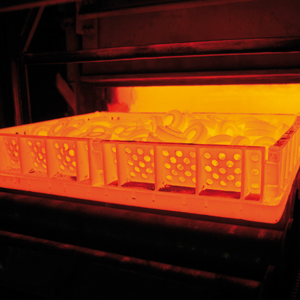

| Mold & Die Making | Cooling channels, mold bases, and cores. |

| Heavy Engineering | Hydraulic cylinders, pump bodies, and turbines. |

| Nuclear & Energy | Heat exchangers, reactor components, and turbine parts. |

Grades and Materials for Deep Hole Drilling:

Deep hole drilling can be performed on a wide variety of materials depending on the application. The materials are selected based on the strength, wear resistance, and thermal properties required by the end product. Common grades and materials include:

| Material | Application |

|---|---|

| Carbon Steel (AISI 1018, 1045) | Used in automotive components and machinery parts. |

| Alloy Steel (EN19, EN24, 4140) | Suitable for aerospace, automotive, and heavy engineering industries. |

| Stainless Steel (316, 304, 17-4 PH) | Common in medical tools, petrochemical equipment, and nuclear industries. |

| Inconel (718, 625) | Preferred in aerospace, oil & gas, and heat exchanger applications. |

| Titanium Alloys (Grade 5, Grade 9) | Used in aerospace, medical, and defense industries due to high strength and corrosion resistance. |

| Aluminum Alloys (6061, 7075) | Suitable for lightweight automotive and aerospace components. |

| Tool Steel (D2, H13, A2) | Common in mold and die making. |

Equipment and Technology for Deep Hole Drilling:

- CNC Deep Hole Drilling Machines: Precision CNC machines are equipped with advanced controls, enabling intricate drilling patterns with high repeatability.

- Gun Drills & BTA Tools: These specialized tools are designed to provide maximum accuracy and efficiency during the drilling process.

- Coolant Systems: High-pressure coolant systems are essential to cool the drill, flush out chips, and ensure smooth drilling even in hard-to-machine materials.

Benefits of Deep Hole Drilling Services:

- Time Efficiency: Specialized equipment allows faster drilling with consistent quality, saving valuable production time.

- Reduced Costs: Efficient chip removal and high-quality surface finish eliminate the need for post-drilling operations, lowering overall costs.

- Versatility: Deep hole drilling is applicable to various industries, offering a broad range of hole sizes, depths, and materials.

- Improved Component Performance: Holes drilled using this process ensure better performance in applications like fluid transmission, structural integrity, and mechanical strength.

Custom Solutions for Your Deep Hole Drilling Needs:

At Textron Steel and Alloys, we provide custom deep hole drilling solutions tailored to your specific project requirements. Whether you need small diameter precision holes for medical tools or large, deep bores for oil & gas components, we have the expertise and technology to deliver.