Carbon Steel Plates: A Comprehensive Guide

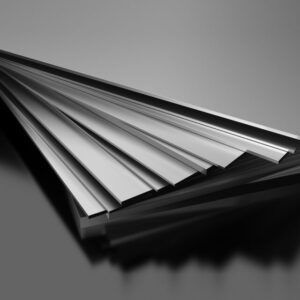

Carbon Steel Plates are among the most commonly used types of steel, known for their excellent combination of strength, durability, and versatility. They are primarily composed of iron and carbon, with trace amounts of other elements like manganese, silicon, and copper. The carbon content significantly influences the properties of the steel, with higher carbon levels resulting in increased hardness and strength but reduced ductility and weldability.

Carbon steel plates are widely used across various industries such as construction, manufacturing, transportation, oil and gas, and shipbuilding due to their cost-effectiveness and reliable performance.

Key Characteristics of Carbon Steel Plates

- Strength: Carbon steel plates offer high strength, especially as the carbon content increases. This strength makes them suitable for load-bearing applications in construction and heavy machinery.

- Durability: The durability of carbon steel plates allows them to withstand wear and tear in harsh conditions, making them ideal for applications where long service life is essential.

- Cost-Effective: Carbon steel is more affordable than alloy steels or stainless steel, making it an economical choice for many industries.

- Good Weldability: Low and medium-carbon steel plates are relatively easy to weld and fabricate, which is why they are commonly used in construction and manufacturing industries.

- Versatility: Carbon steel plates are available in a wide range of grades and thicknesses, allowing them to be used in various applications, from structural components to pressure vessels.

- Thermal Conductivity: Carbon steel has good thermal conductivity, making it suitable for use in heat exchangers and other temperature-sensitive applications.

Types of Carbon Steel Plates

Carbon steel plates are generally categorized based on their carbon content into the following types:

1. Low Carbon Steel Plates (Mild Steel)

- Carbon Content: 0.05% – 0.25%

- Characteristics: Low carbon steel plates are soft, highly ductile, and easy to fabricate and weld. They offer moderate strength and are used in applications where toughness and ductility are prioritized over hardness and strength.

- Applications: Construction materials, structural shapes, machinery parts, and automobile components.

2. Medium Carbon Steel Plates

- Carbon Content: 0.25% – 0.60%

- Characteristics: Medium carbon steel offers a balance between strength and ductility. It has better toughness and wear resistance compared to low carbon steel, but it is harder to weld and machine.

- Applications: Railway tracks, automotive components, axles, crankshafts, and forging parts.

3. High Carbon Steel Plates

- Carbon Content: 0.60% – 1.0%

- Characteristics: High carbon steel plates are harder and stronger but less ductile and more brittle. Due to their increased hardness, they are more difficult to weld and machine, making them suitable for applications requiring high wear resistance.

- Applications: Cutting tools, knives, springs, and high-strength wires.

4. Ultra-High Carbon Steel Plates

- Carbon Content: 1.0% – 2.0%

- Characteristics: Ultra-high carbon steel is extremely hard and brittle. It is often used in applications requiring very high wear resistance and strength but limited flexibility and ductility.

- Applications: Blades, drill bits, and cutting tools.

Common Grades of Carbon Steel Plates

Carbon steel plates come in various grades, each designed for specific uses and industry standards. Here are some of the most widely used grades:

| Grade | Carbon Content | Tensile Strength (MPa) | Applications |

|---|---|---|---|

| ASTM A36 | 0.20% | 400-550 | Structural steel, bridges, buildings, oil platforms |

| ASTM A283 (Grade C) | 0.24% | 380-515 | General structural purposes, tanks, machinery components |

| ASTM A516 (Grade 70) | 0.28% | 485-620 | Pressure vessels, boilers, heat exchangers |

| EN 10025 S275JR | 0.18% | 370-530 | Structural steel, bridges, and other construction applications |

| EN 10025 S355JR | 0.23% | 470-630 | Structural steel, high-load applications such as cranes and towers |

| SAE 1045 (C45) | 0.45% | 570-700 | Automotive components, axles, machinery parts |

| ASTM A573 | 0.25%-0.35% | 485-620 | Structural steel, bridges, storage tanks, and welded structures |

Breakdown of Key Grades:

- ASTM A36: This is one of the most popular grades of carbon steel, primarily used for structural purposes. It has good weldability and machinability, making it ideal for applications like bridges, buildings, and oil platforms.

- ASTM A283: This grade is suitable for low and intermediate tensile strength structural applications, such as general structural purposes, tanks, and machinery components.

- ASTM A516 Grade 70: This grade is designed for use in pressure vessels and boilers. It offers excellent toughness and resistance to brittle fractures, making it ideal for high-pressure and high-temperature applications in oil and gas refineries, petrochemical plants, and power stations.

- EN 10025 S275JR and S355JR: These European standard grades are commonly used for structural steel applications in bridges, buildings, and construction machinery. S355JR offers higher strength than S275JR and is suitable for high-load structures.

Applications of Carbon Steel Plates

Carbon steel plates are used across many industries due to their versatility and cost-effectiveness. Some of the most common applications include:

1. Construction Industry

Carbon steel plates are widely used in construction due to their strength and affordability. They are used in the fabrication of buildings, bridges, steel structures, and reinforced concrete. Low-carbon grades like ASTM A36 are often used for these purposes because of their good weldability and machinability.

2. Pressure Vessels and Boilers

Grades like ASTM A516 Grade 70 are specifically designed for pressure vessels and boilers, where the steel needs to withstand high pressure and temperature. These plates are used in the oil and gas industry, power plants, and chemical processing industries.

3. Shipbuilding

Carbon steel plates are used in the shipbuilding industry to construct the hulls, decks, and structural components of ships. Grades like ASTM A131 are specifically designed to meet the needs of marine environments.

4. Automotive Industry

In the automotive industry, carbon steel plates are used to manufacture parts like axles, frames, and body panels. Medium and high-carbon grades are commonly used in components that require higher strength and wear resistance.

5. Machinery and Equipment

Carbon steel plates are used to manufacture a wide variety of machinery and equipment components. Medium-carbon steel is commonly used in the production of gears, shafts, axles, and other mechanical parts where strength and wear resistance are essential.

6. Oil and Gas Industry

In the oil and gas industry, carbon steel plates are used for pipelines, pressure vessels, storage tanks, and drilling rigs. They must withstand harsh conditions, including high pressure and exposure to corrosive materials.

7. Railway and Transportation

Carbon steel plates are also used in railway tracks, train components, truck frames, and trailers, where strength, toughness, and impact resistance are crucial.

Advantages of Carbon Steel Plates

- Affordability: Carbon steel plates are generally more affordable than alloy or stainless steel plates, making them cost-effective for many industries.

- Strength and Durability: Carbon steel plates offer excellent strength and durability, which is why they are widely used in construction and heavy machinery.

- Good Weldability and Machinability: Low and medium carbon steel plates are relatively easy to weld, form, and machine, allowing them to be used in various manufacturing processes.

- Availability in a Range of Thicknesses: Carbon steel plates are available in different thicknesses and sizes, making them suitable for various applications.

- Wide Range of Applications: Due to their versatility, carbon steel plates can be used in everything from simple structural components to high-pressure vessels.

Limitations of Carbon Steel Plates

- Corrosion Susceptibility: Carbon steel, especially low-carbon steel, is more susceptible to corrosion than alloy steels or stainless steel. Additional protective coatings or treatments like galvanization may be necessary for applications exposed to moisture or harsh chemicals.

- Brittleness at High Carbon Levels: High carbon content can make the steel brittle, which limits its use in applications where flexibility and ductility are required.

- Difficult to Weld and Machine (for High Carbon Grades): High-carbon steel plates can be challenging to weld and machine due to their hardness.

- Low Resistance to Wear and Heat: Low-carbon steel offers limited resistance to wear and high temperatures, restricting its use in environments that require high wear or heat resistance.

Showing all 15 results

-

50CrV4 Sheet

Read more -

A283 Grade C Plate

Read more -

A387 GRADE 22 CLASS 2

Read more -

A387 GRADE 5 CLASS 2

Read more -

ASTM A36 Plate

Read more -

C45 Plates | Sheets

Read more -

EN19 Plates

Read more -

EN42G Sheet

Read more -

EN8 Plate

Read more -

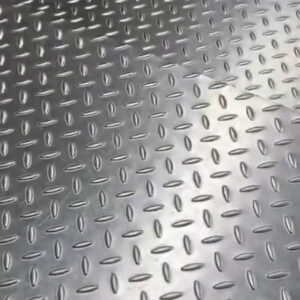

IS 3502 Chequered Plates

Read more -

Rockstar 400 Plates

Read more -

Rockstar 450 Plates

Read more -

Rockstar 500 Plates

Read more -

Welten 780E Plates / Sheets

Read more -

X120MN12 / SIDUR 3401

Read more