Description

CNC Machining Services

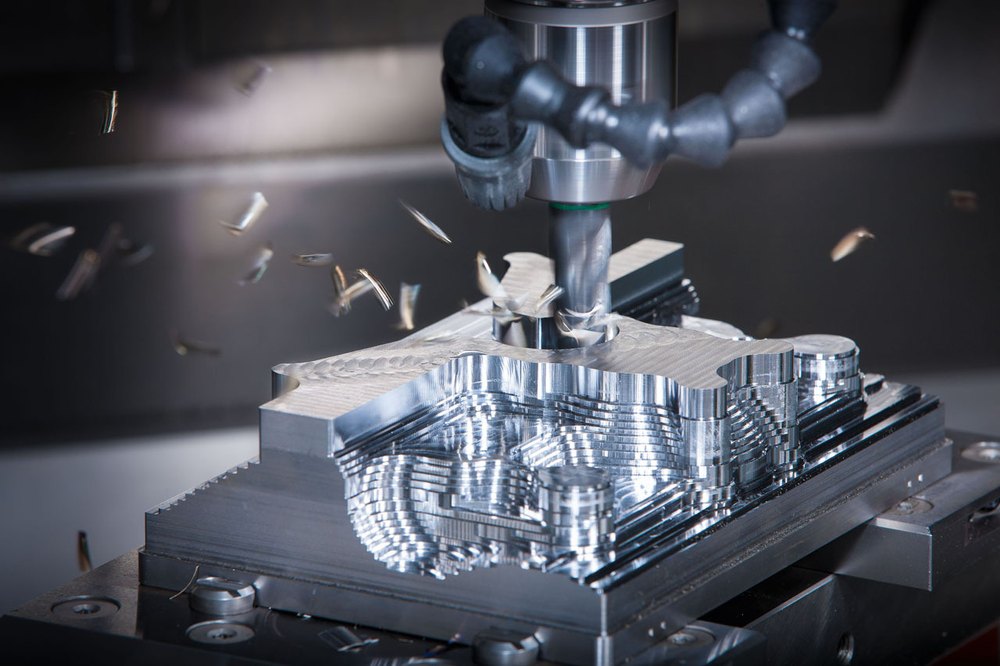

CNC machining services provide precision manufacturing solutions by using Computer Numerical Control (CNC) machines to produce high-accuracy components from various materials. These services involve the automated control of machine tools (like lathes, mills, routers, and grinders) through pre-programmed software and code that dictates the movement of the equipment. CNC machining is ideal for manufacturing complex parts with tight tolerances, excellent repeatability, and high efficiency, making it indispensable in industries like aerospace, automotive, medical, and electronics.

CNC machining services offer a wide range of capabilities, including turning, milling, drilling, tapping, and grinding. They are used to fabricate parts from metals, plastics, composites, and even advanced materials like titanium and Inconel. CNC machines can work on prototypes as well as full production runs, providing flexibility for both small and large projects.

Key Features of CNC Machining Services

- High Precision: CNC machines offer unparalleled accuracy and tight tolerances, allowing the production of complex parts that require precise dimensions and geometries.

- Consistency and Repeatability: CNC machining ensures consistency across multiple production runs, producing identical parts with minimal variation.

- Automation and Efficiency: CNC machines operate autonomously once programmed, improving productivity, reducing human error, and optimizing production time.

- Flexibility in Material Selection: CNC machining can handle a wide range of materials, from soft plastics to hard metals, providing versatility for different applications.

- Complex Geometry: CNC machines can manufacture parts with intricate shapes and complex geometries that are challenging or impossible to produce with traditional machining methods.

- Cost-Effectiveness: For high-volume production, CNC machining can lower labor costs and material waste, offering an efficient solution for large-scale manufacturing.

Applications of CNC Machining Services

- Aerospace Industry: CNC machining is crucial in the aerospace industry for producing complex components such as turbine blades, engine parts, and structural components. Aerospace parts must meet stringent quality and safety standards, requiring high precision and durability.

- Automotive Industry: CNC machines manufacture a wide range of automotive components, including engine blocks, gears, transmissions, and custom car parts. The precision and speed of CNC machining improve the performance and reliability of automotive systems.

- Medical Industry: Medical devices, surgical instruments, and implants require the precision and accuracy that CNC machining provides. Titanium implants, stainless steel surgical tools, and other critical medical components benefit from CNC’s ability to meet tight tolerances and biocompatibility requirements.

- Electronics Industry: CNC machining is used to produce small, intricate parts such as circuit boards, connectors, and enclosures for electronic devices. The high accuracy and repeatability ensure reliable performance in devices like smartphones, computers, and medical electronics.

- Defense and Military: CNC machining services support the defense sector by manufacturing high-performance parts like firearms, missile components, and radar systems. These parts must be durable and reliable to withstand extreme environments and meet stringent military specifications.

- Industrial Equipment: CNC machining is essential for fabricating industrial machinery components, such as gears, bearings, shafts, and housings. CNC’s precision and strength help ensure the reliability and longevity of heavy-duty equipment.

- Robotics and Automation: Robotics companies rely on CNC machining to produce custom parts for robot arms, sensors, frames, and precision gears. The accuracy and ability to produce intricate parts are essential in building high-performance automation systems.

Grades of Materials Used in CNC Machining

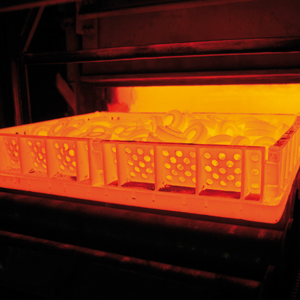

CNC machining services can handle a wide variety of materials, from metals to plastics, composites, and advanced alloys. The choice of material depends on the specific requirements of the application, such as strength, heat resistance, or corrosion resistance.

| Material Grade | Type | Applications |

|---|---|---|

| Aluminum 6061 | Aluminum Alloy | Aerospace, automotive parts, and consumer electronics due to its lightweight properties and corrosion resistance |

| Aluminum 7075 | High-Strength Aluminum Alloy | Aircraft and aerospace components requiring high strength-to-weight ratio |

| Steel 1018 | Carbon Steel | Structural parts, shafts, and industrial machinery components for its excellent machinability and weldability |

| Steel 4140 | Alloy Steel | High-stress applications such as gears, axles, and crankshafts due to its toughness and fatigue resistance |

| Stainless Steel 304 | Austenitic Stainless Steel | Food processing, medical instruments, and marine environments for corrosion resistance and strength |

| Stainless Steel 316 | Austenitic Stainless Steel | Marine and chemical processing industries requiring superior corrosion resistance |

| Titanium Grade 5 (Ti-6Al-4V) | Titanium Alloy | Aerospace, medical implants, and automotive parts requiring high strength, low weight, and biocompatibility |

| Inconel 718 | Nickel Alloy | High-temperature and high-stress environments such as gas turbines and aerospace components |

| Brass C360 | Copper Alloy | Electrical components, fittings, and fasteners due to its high machinability and conductivity |

| ABS Plastic | Thermoplastic | Consumer products, electronics housings, and automotive parts for its lightweight and impact resistance |

| POM (Delrin) | Engineering Plastic | Gears, bearings, and mechanical components requiring low friction and high wear resistance |

| PEEK | High-Performance Polymer | Aerospace, medical devices, and chemical equipment for its high temperature and chemical resistance |

Benefits of CNC Machining Services

- Unmatched Precision: CNC machining achieves extremely tight tolerances, making it ideal for industries that require high precision, such as aerospace and medical.

- Quick Turnaround Time: CNC machining reduces production time with automated processes, increasing efficiency and enabling fast delivery of parts.

- Complexity in Design: CNC machines can fabricate intricate and complex designs with ease, including 3D geometries and internal cavities.

- Scalability: CNC machining is suitable for both prototyping and mass production, allowing manufacturers to scale up production as needed.

- Material Versatility: CNC machines can process a wide range of materials, from metals and plastics to advanced alloys, making them adaptable to different industries and applications.

- Reduced Waste: CNC machining minimizes material waste due to its precision and efficiency, leading to cost savings and sustainable manufacturing practices.