Description

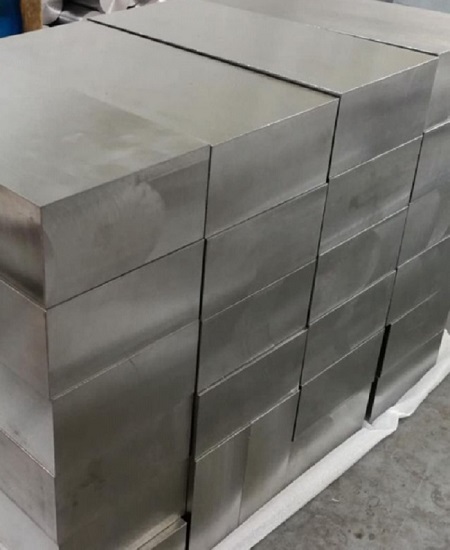

Custom Forged Stainless Steel Blocks

Custom forged stainless steel blocks are highly durable, corrosion-resistant components designed to meet the rigorous demands of various industries. These blocks are produced through a forging process where stainless steel billets are shaped under extreme pressure to achieve superior mechanical properties such as enhanced strength, toughness, and durability. Forging stainless steel blocks provides numerous advantages, including improved grain structure, better resistance to wear and corrosion, and the ability to be customized in terms of size, shape, and material grade to suit specific applications.

Stainless steel blocks are essential in industries where high performance, reliability, and resistance to harsh environments are crucial. Custom forged blocks are widely used in applications such as manufacturing machinery, aerospace, marine, oil and gas, chemical processing, and heavy-duty construction equipment.

Key Features of Custom Forged Stainless Steel Blocks

- Corrosion Resistance: Stainless steel’s inherent corrosion resistance makes these blocks ideal for use in environments exposed to moisture, chemicals, and extreme temperatures.

- Superior Strength: The forging process enhances the strength and toughness of stainless steel blocks, making them capable of withstanding high loads and stresses.

- Wear Resistance: Forged stainless steel blocks exhibit excellent wear resistance, providing long-term durability even in high-friction environments.

- Customizability: Stainless steel blocks can be forged to precise specifications, including size, shape, and grade, ensuring they meet the specific needs of various applications.

- Improved Grain Structure: Forging refines the grain flow of the material, resulting in better mechanical properties and resistance to fatigue and impact.

Applications of Custom Forged Stainless Steel Blocks

- Aerospace Industry: Stainless steel blocks are used in aerospace applications, including engine components, structural parts, and landing gear, where high strength, corrosion resistance, and precision are essential.

- Oil & Gas Industry: In the oil and gas sector, stainless steel blocks are used for drilling equipment, valves, and pressure vessels, where they provide durability and corrosion resistance in high-pressure environments.

- Marine Industry: Due to their excellent resistance to seawater corrosion, custom forged stainless steel blocks are employed in shipbuilding, offshore platforms, and marine equipment.

- Chemical Processing: Stainless steel blocks are widely used in the chemical and petrochemical industries, where they are exposed to corrosive chemicals and require high resistance to pitting and oxidation.

- Manufacturing & Heavy Machinery: Forged stainless steel blocks are critical components in manufacturing machinery, offering the necessary strength and wear resistance for heavy-duty operations.

- Defense Industry: Custom forged stainless steel blocks are used in the defense sector for the production of weapons systems, armored vehicles, and other high-performance military equipment that requires superior durability and precision.

- Food & Pharmaceutical Industries: In food processing and pharmaceutical applications, stainless steel blocks are essential due to their hygienic properties, resistance to corrosion, and ease of cleaning.

Grades of Custom Forged Stainless Steel Blocks

The choice of stainless steel grade for forged blocks depends on the specific application, environment, and performance requirements. Commonly used grades include austenitic, martensitic, and duplex stainless steels, each offering unique characteristics suited to different industries.

| Material Grade | Type | Applications |

|---|---|---|

| SS304 | Austenitic Stainless Steel | General-purpose applications, food processing, chemical equipment |

| SS316 | Austenitic Stainless Steel | Marine environments, chemical processing, and pharmaceutical industries |

| SS410 | Martensitic Stainless Steel | Valves, pumps, and other high-wear components requiring hardness and toughness |

| SS420 | Martensitic Stainless Steel | Cutting tools, surgical instruments, and high-strength machinery components |

| SS321 | Austenitic Stainless Steel | Aerospace components, heat exchangers, and high-temperature environments |

| Duplex 2205 | Duplex Stainless Steel | Oil & gas, chemical processing, and marine applications requiring high strength and corrosion resistance |

| Super Duplex 2507 | Super Duplex Stainless Steel | Offshore platforms, desalination plants, and chemical processing environments |

| SS904L | Austenitic Stainless Steel | Chemical and petrochemical industries, where resistance to aggressive chemicals is required |

Benefits of Custom Forging for Stainless Steel Blocks

- High-Performance Durability: Forged stainless steel blocks provide superior durability and performance in high-stress environments, ensuring longer service life and reliability.

- Corrosion and Wear Resistance: The corrosion resistance of stainless steel, combined with the forging process, results in blocks that are ideal for harsh environments, including chemical processing and marine industries.

- Precision Engineering: Forged blocks can be produced with precise dimensions, ensuring that they meet the specific requirements of the application and fit perfectly into machinery or structural frameworks.

- Cost-Effective Solution: Despite the higher initial cost of forged components, their increased longevity, reduced maintenance needs, and better performance in challenging conditions offer a cost-effective solution in the long term.

- Wide Range of Applications: Custom forged stainless steel blocks can be used across a diverse range of industries, making them a versatile solution for many engineering challenges.