Description

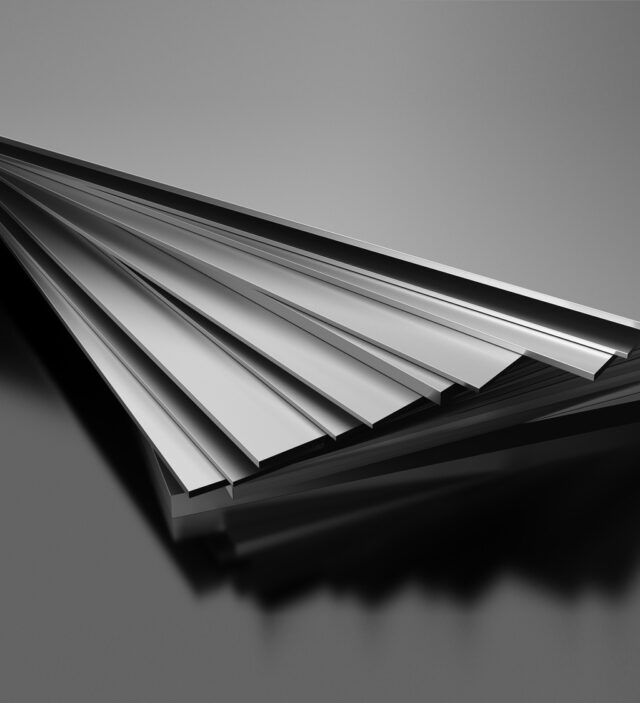

- EN8 Plate: Properties, Applications, and Key Features

EN8 (also known as 080M40 in the British Standards) is a medium carbon steel grade that is widely used for general engineering applications. EN8 plates are particularly valued for their good machinability, moderate tensile strength, and balanced toughness. These characteristics make EN8 an ideal material for components that require medium strength and are subject to wear, impact, and moderate stress levels.

Chemical Composition of EN8 Steel

The chemical composition of EN8 steel primarily includes carbon and manganese, along with small amounts of other alloying elements. The typical chemical composition of EN8 steel is as follows:

Element Percentage (%) Carbon (C) 0.36 – 0.44 Manganese (Mn) 0.60 – 1.00 Silicon (Si) 0.10 – 0.40 Sulfur (S) 0.05 (max) Phosphorus (P) 0.05 (max) The relatively high carbon content of EN8 (compared to low carbon steels) enhances its strength and hardness, especially when heat-treated.

Mechanical Properties of EN8 Plates

The mechanical properties of EN8 steel make it suitable for applications that require both moderate strength and hardness. Below are some key mechanical properties of EN8 steel in its normalized condition:

Property Value Tensile Strength 550 – 700 MPa Yield Strength 280 – 440 MPa Elongation 16 – 18% Hardness (Brinell) 150 – 210 HB Impact Strength (Izod) 54J (typically) EN8 plates exhibit a good balance between hardness and toughness, making them ideal for parts subject to impact and wear but not extreme high-stress conditions.

Heat Treatment of EN8 Steel

EN8 steel can be heat-treated to further improve its mechanical properties. Some of the common heat treatments applied to EN8 plates include:

- Normalizing: Heating the steel to a temperature of 830°C – 860°C and then allowing it to air cool. This process refines the grain structure and improves strength and toughness.

- Annealing: Heating the EN8 plate to 680°C – 710°C, followed by slow cooling. Annealing softens the steel, making it more machinable.

- Hardening and Quenching: Heating the steel to a temperature of 820°C – 860°C, followed by rapid cooling in oil or water. This process increases hardness but may reduce ductility.

- Tempering: After hardening, EN8 steel is typically tempered at a lower temperature (around 550°C – 660°C) to balance strength and toughness by reducing brittleness.

Key Features of EN8 Plates

- Good Machinability: EN8 plates are easy to machine in their normalized or annealed state, making them ideal for machining processes like turning, drilling, and milling.

- Moderate Strength: EN8 steel provides moderate tensile strength and hardness, making it suitable for medium-stress applications where toughness and wear resistance are important.

- Heat Treatability: EN8 can be hardened and tempered to improve its wear resistance, hardness, and toughness, allowing it to meet the specific requirements of different engineering applications.

- Versatile Application: The combination of strength, toughness, and machinability makes EN8 suitable for a wide range of general engineering applications.

- Affordability: EN8 plates are cost-effective compared to alloy steels or higher-strength materials, making them popular in industries where both performance and cost are key considerations.

Common Applications of EN8 Steel Plates

EN8 plates are widely used in industries that require parts and components with moderate strength and wear resistance. Some typical applications include:

- Shafts and Axles: EN8 steel is commonly used to manufacture shafts, drive shafts, and axles due to its toughness and moderate strength, which can withstand rotational stresses and wear.

- Gears: EN8 is suitable for gears that require good wear resistance and the ability to handle moderate loads, especially after hardening and tempering.

- Bolts, Nuts, and Fasteners: EN8 plates are used to create bolts, nuts, studs, and fasteners, where moderate strength and wear resistance are required.

- Connecting Rods: Connecting rods and other mechanical parts subjected to cyclical loading are often made from EN8 due to its toughness and fatigue resistance.

- Crankshafts: EN8 steel is also used for crankshafts in machinery and vehicles, where moderate strength and impact resistance are essential.

- Forged Components: The ability to heat-treat EN8 makes it ideal for producing forged components, such as couplings, pins, spindles, and machinery parts, that require improved toughness and wear resistance.

- Agricultural Equipment: EN8 plates are also used in the production of agricultural machinery and tools, where moderate wear resistance and toughness are important.

Advantages of EN8 Plates

- Balanced Mechanical Properties: EN8 plates offer a good balance between strength, toughness, and machinability, making them suitable for a wide range of engineering applications.

- Cost-Effective: EN8 steel is a medium carbon steel, which is more affordable than alloy steels, providing cost savings while still meeting performance requirements.

- Heat Treatment Flexibility: EN8 plates can be heat-treated to enhance specific properties, such as hardness or toughness, for different applications.

- Easy to Machine: The machinability of EN8 is better than that of higher carbon steels, making it easier to process into complex shapes and components.

Limitations of EN8 Plates

- Lower Corrosion Resistance: Like most carbon steels, EN8 is prone to corrosion if exposed to moisture or harsh environments, and may require coating or protection for outdoor applications.

- Limited Weldability: While EN8 can be welded, special precautions such as preheating and post-weld heat treatment are often necessary to avoid cracking.

- Not Suitable for High-Stress Applications: EN8 is not ideal for applications where extremely high strength or toughness is required, such as in very high-load components.