Description

S235JR Structural Steel

Table of Contents

- Introduction to S235JR Structural Steel

- S235JR Steel Properties

- 2.1 Mechanical Properties

- 2.2 Chemical Composition

- S235JR Steel Grades

- 3.1 Understanding the Grades

- Applications of S235JR Steel

- 4.1 Construction Industry

- 4.2 Manufacturing and Fabrication

- 4.3 Transportation Industry

- Advantages of Using S235JR Steel

- Comparison of S235JR with Other Structural Steels

- 6.1 S235JR vs S275JR

- 6.2 S235JR vs S355JR

- Conclusion

1. Introduction to S235JR Structural Steel

S235JR is a European standard non-alloy structural steel grade, designated under the EN 10025-2: 2004 standard. It is one of the most commonly used steels for general structural purposes due to its versatility, cost-effectiveness, and availability in various forms and thicknesses. “S” in S235JR stands for structural steel, while “235” refers to the minimum yield strength of the steel in MPa (235 MPa). The “JR” symbol indicates that the steel has been impact-tested to withstand a 27J energy at room temperature, following the Charpy impact test.

2. S235JR Steel Properties

S235JR structural steel offers a balance between strength, weldability, and ductility, making it a popular choice in construction and manufacturing. Below is a closer look at its key mechanical properties and chemical composition:

2.1 Mechanical Properties

| Property | Value |

|---|---|

| Yield Strength | 235 MPa (minimum) |

| Tensile Strength | 360-510 MPa |

| Elongation (A) | 20-22% |

| Impact Energy (Charpy V) | 27J (at room temperature) |

2.2 Chemical Composition

| Element | Maximum Percentage (%) |

|---|---|

| Carbon (C) | 0.17 |

| Manganese (Mn) | 1.40 |

| Phosphorus (P) | 0.035 |

| Sulfur (S) | 0.035 |

| Nitrogen (N) | 0.012 |

| Copper (Cu) | 0.55 |

3. S235JR Steel Grades

S235JR belongs to the EN 10025 standard and is one of the lower grades of structural steel. The “JR” symbol distinguishes it from other steel grades like S235J0 and S235J2, which refer to different impact toughness levels. Here’s a brief overview of these grades:

- S235JR: Tested for 27J at room temperature.

- S235J0: Tested for 27J at 0°C.

- S235J2: Tested for 27J at -20°C.

The different grades of S235 steel allow engineers and designers to choose the most suitable option based on environmental conditions and performance requirements.

4. Applications of S235JR Steel

S235JR is widely used in a variety of industries due to its high strength, weldability, and good machinability. Below are the major application areas:

4.1 Construction Industry

S235JR is extensively used in the construction of bridges, buildings, and other infrastructure projects. Its ability to withstand various loads, including compression and tension, makes it ideal for structural applications like steel frames, beams, columns, and trusses.

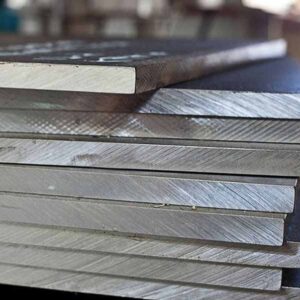

4.2 Manufacturing and Fabrication

In the manufacturing and fabrication industry, S235JR is commonly used for creating steel plates, sheets, and profiles. These components are further processed into machine parts, support structures, and frames. The weldability of this grade allows easy assembly and joining during fabrication.

4.3 Transportation Industry

In the transportation sector, S235JR is used for producing parts of railways, ships, and automobiles. Its versatility, along with its mechanical properties, makes it a cost-effective solution for transportation-related structures that need to resist dynamic stresses and strains.

5. Advantages of Using S235JR Steel

S235JR structural steel comes with several advantages, making it a top choice for general structural purposes:

- Cost-effective: Widely available at a reasonable cost.

- Good Weldability: Compatible with most welding processes.

- Versatility: Available in different shapes like plates, sections, and profiles.

- Corrosion Resistance: Can be enhanced by galvanization.

- Ductility: High elongation rate allows it to bend without breaking under load.

6. Comparison of S235JR with Other Structural Steels

S235JR has a specific set of mechanical properties, but how does it compare with other common structural steels?

6.1 S235JR vs S275JR

S275JR offers a slightly higher yield strength of 275 MPa compared to the 235 MPa of S235JR, making it more suitable for heavy-duty applications. However, S235JR is more cost-effective for lighter structural applications.

6.2 S235JR vs S355JR

S355JR is a higher-grade structural steel with a yield strength of 355 MPa. It is used for more demanding structural applications where higher strength and toughness are required. S235JR, on the other hand, is a more economical option for general structural purposes.