Description

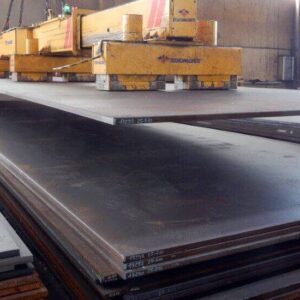

S275JR Structural Steel Plate Stockist in India As Per EN 10025-2:2004

S275JR Plate Specification

S275JR Plate Stockist in India in Custom Sizes For Structural Application

| Specification | Details |

|---|---|

| Standard | EN 10025-2:2004 |

| Width | 1000mm-4500mm |

| Thickness | 5mm-150mm |

| Length | 3000mm-18000mm |

| Hardness | As per NACE MR 175 |

| Welding | Can be welded without limitations |

| Impact tested | -52° C |

| Classification | Non-alloy structural steel |

| Processing | Welding, Cutting, Drilling, Bending, etc. |

| Process | Hot-Rolled (HR) |

| Delivery State | AR, HR, N |

| Surface Finish | Anti Rust Oiled, PE Coated, Anti Rust Varnished, Galvanized, Color Coated, Black Painted |

| Third Party Inspection (TPI) | BV, SGS, Intertek, etc. |

| Packaging | Plastic Bags, Wooden Boxes |

| Origin | Indian, Japanese, Korean, USA, Russian, European, Ukraine |

Mild Steel S275JR Plate Thickness Tolerance

| Thickness (T) mm | Tolerance Band |

|---|---|

| ≤ 1200 | > 2.5 ≤ 3.0 ±0.20 |

| > 1200 ≤ 1500 | > 2.5 ≤ 3.0 ±0.22 |

| > 1500 ≤ 1800 | > 2.5 ≤ 3.0 ±0.22 |

| > 4.0 ≤ 5.0 | ±0.24 |

| > 3.0 ≤ 4.0 | ±0.22 |

| > 5.0 ≤ 6.0 | ±0.26 |

| > 8.0 ≤ 10.0 | ±0.32 |

| > 10.0 ≤ 12.5 | ±0.35 |

Equivalent of S275JR Steel Plates

| EN | UNI | JIS | DIN/WNr | IS | AFNOR | ISO | ASTM |

|---|---|---|---|---|---|---|---|

| S275JR | Fe430B | SS400 | RSt42-2 | IS2062 | E28-2 | E275B | A283D |

| St 44-2 | A529 Gr.D |

Weight of EN 10025-2 S275JR Structural Steel Plate

| LxW (mm) | T (mm) | Kg/e |

|---|---|---|

| 2000 x 1000 | 4.0 | 62.8 |

| 2.0 | 31.4 | |

| 1.5 | 23.6 | |

| 3.0 | 47.1 | |

| 6.0 | 94.2 | |

| 5.0 | 78.5 | |

| 10.0 | 157.0 | |

| 8.0 | 125.6 | |

| 3000 x 1500 | 6.0 | 212.0 |

| 4.0 | 141.3 | |

| 3.0 | 106.0 | |

| 5.0 | 176.6 | |

| 10.0 | 353.3 | |

| 8.0 | 282.6 | |

| 2500 x 1250 | 4.0 | 98.1 |

| 2.0 | 49.1 | |

| 1.5 | 36.8 | |

| 3.0 | 73.6 | |

| 6.0 | 147.2 | |

| 5.0 | 122.7 | |

| 10.0 | 245.3 | |

| 8.0 | 196.3 | |

| 12.0 | 294.4 |

EN 10025-2 S275JR Plate Chemical Composition

| C for nominal thickness in mm | Mn | P | S | N | Cu |

|---|---|---|---|---|---|

| ≤ 16 | ≤ 0.21 | ≤ 0.035 | ≤ 0.035 | ≤ 0.012 | ≤ 0.55 |

| ˃ 16 ≤ 40 | ≤ 0.21 | ≤ 0.045 | ≤ 0.045 | ||

| ˃ 40 | ≤ 0.22 |

Difference Between S275JR and S355JR

| Property | S275JR | S355JR |

|---|---|---|

| Tensile Strength | 430-550 MPa | 470-630 MPa |

| Machinability | Generally good | Generally good; may require careful handling due to higher strength |

| Yield Strength | 275 MPa (minimum) | 355 MPa (minimum) |

| Chemical Composition | Higher Manganese, Lower Carbon | Balanced Manganese and Silicon, Slightly Higher Carbon |

| Elongation | 26% | 22% |

| Applications | General construction, structural applications where lower strength is acceptable | Demanding structural applications requiring higher strength and toughness |

| Weldability | Good | Good; requires stringent control due to higher strength |

Get S275JR Pressure Vessel Plate From Genuine Dealers and Distributors For Structural Applications