OUR MANUFACTURING FACILITIES & CAPABILITIES, OUR MANUFACTURING FACILITY

SUITABLE INFRASTRUCTURE

Located in one in every of most promising cities of India – MUMBAI, A.M. ENGINEERING has superior infrastructural environment.

- 36000 Sqft properly designed & supplied work

- 300+ Staff and worker3Committed parking for all office personalsDevoted dining location with the ability of 150+ personals

- Committed server rooms

- Nation of artwork convention rooms with video & audio convention centers

- Secured wireless community facility

- 24/7 backup electricity availability

- The targeted catastrophe recovery planVersion manage software for handling client code (SVN)

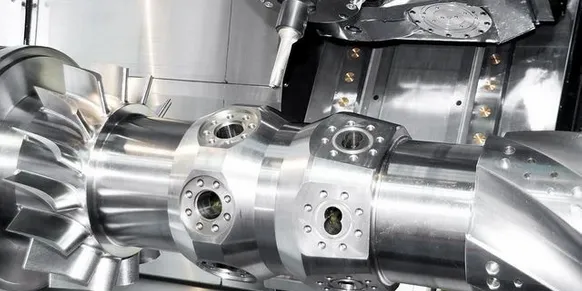

CNC VMC 5 AXIS MACHINING

A.M. Engineering has its own in-house advance CNC VMC basee machining facility, this allow us to achieve high class Machining solution and create a unique custom designed solution from our Machining works.

Lathe Machining, drilling, milling, boring, deep hole drilling, plano miller, slotting, shaper Machining allow us to Manufacture fine and exact job/workpiece as per customer's or standard requirements.

Size range - From Diameter 3 mm to 3000 mm and job/workpiece length up to 12000 mm and Single job weight up to 35,000 kg.

GRINDING & HONING

The honing facility provides us the final sizing and creates the desired finish size inside bore of tubing or cylinder bores. Finishing is finished by increasing abrasive stones of appropriate grit and grade against the paintings surface. The stones are rotated and reciprocated in the part with hone abrasive below managed stress. Combining rotation and reciprocation produces a pass-hatch pattern within the surface of the element being honed. Honed tube, Honed pipe, Hydrulic cylinders are made from the process.

Size range from HONING 10MM - 1200 MM Inside diameter & total length/deep up to 12000 MM (12meter)

ERW STEEL PIPE MARKING , SPIRAL PIPE MARKING, LSAW & SSAW PIPE MAKING

Pipe and Tubes with diameters of between 10 mm and 3000 mm and wall thicknesses from 0.7-70 MM and length up to 14 meter

Using rolls and die from hot and cold forming type A.M. Engineering is Manufacturing High precision tubes for the automotive and mechanical engineering sectors Line pipes, casings, tubings and drill pipes for oil, gas, Engineering & chemical regions. Structural tubes and pipes with spherical, square and square pass-sections are Manufacturerd from the process.

Other facilities for Manufacturing the pipe and tubes are added as below,

Inner flash flushing stations Straightening machines Pipe give up facing and chamfering unit Threading machines Hydrostatic pipe testers Statistics identification structures (AMS) Bundling stations and switch structures

GEAR CUTTING/GEAR MACHINING, HOBBING

Our system is perfect for precision gear Machining both small and huge diameter gears. Gear cutting abilities encompass spur, helical, bevel and bull gears, as well as more than one types of sprockets, timing pulleys, shafts and splines.

Our capacity for gear cutting and making are from diameters 20 MM to 3000 MM

HEAT TREATMENT

Heat treatment involves the usage of heating or cooling to intense temperatures, to obtain the desired result which include hardening or softening of a steel. Heat treatment techniques encompass annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching etc these all treatments are used for making steel more better and suitable for Forging, Machining and improving life of metals. Our heating furnace is suitable for workpiece up to weigh of 40 Metric Ton

FORGING HAMMER AND FORGING PRESS

Through the years A.M. Engineering has created world-class capacities and skills. Our forging centers includes absolutely automated forgings press traces starting from 1000T to 19000T. All the forging press strains are extraordinarily flexible,Our Close die forgings machine allow us Forge in actual required Shape for avoid Extra use for materials which comes from Manufacturing size range from 100 Grams to 300KG of single Components in close die forgings which gives the organization the inherent gain to simultaneously meet extraordinary purchaser demands and optimize manufacturing. This allows A.M Engineering to fulfill the growing demands of its clients constantly.Through the years A.M. Engineering has created world-class capacities and skills. Our forging centers includes absolutely automated forgings press traces starting from 1000T to 19000T. All the forging press strains are extraordinarily flexible,Our Close die forgings machine allow us Forge in actual required Shape for avoid Extra use for materials which comes from Manufacturing size range from 100 Grams to 300KG of single Components in close die forgings which gives the organization the inherent gain to simultaneously meet extraordinary purchaser demands and optimize manufacturing. This allows A.M

METAL TESTING FACILITY

A.M. Engineering has the equipment and knowledge to offer a complete-range of testing for better quality out for metals and alloys, which include titanium, chrome steel, alloy steels, copper alloys and aluminum alloys. After this we also provide NABL approved lab testing facilities on customers requirement. Some of our testing facilities are mentioned below

Chemical analysis – instrumental and classical wet chemistry.

Mechanical trying out – wide-variety of checks to measure cloth strength, ductility, hardness, and greater.

Fracture Mechanics – fatigue crack boom and fracture testing.

Metallurgical testing – microscopic, macroscopic and microhardness examinations.

Corrosion checking out – testing for corrosion, salt spray, humidity, passivation and more

Nondestructive testing – ultrasonic, hydrostatic pressure, X-ray, magnetic particle, liquid penetrant.

Specimen making – in-house Machining

DEEP HOLE DRILLING / GUN DRILLING / BTA DRILLING

Deep hole drilling consists of BTA drilling and gun drilling, with additional methods designed for particular tolerance objectives and commonly carried out on BTA-style deep hollow drilling machines.

Deep hole drilling is used in drilling of solid steel shaft or enlarging Inside bore from hollw shaft/Components which are made from aluminum, steel, alloys, stainless steel, etc. and is able to acquire tight diameter tolerance, straightness, and superior floor end into workpieces.

Deep hole drilling processes work via the use of unique machine and setups to supply high pressure coolant, evacuate chips cleanly, we use deep hole drilling machine for drilling holes in solid steel or for enlarging of current inside bore where CNC machine tools can't reach. This allows us to maintain tolerances and production requirements reliably, correctly, and efficiently.

Size range from Minimum diameter 10 to maximum diameter of 1200 MM and length/feel up to 12 meter